WHAT WE DO!

Chlorine dioxide is a chemical compound with the formula ClO2

As one of several oxides of chlorine, it is a potent and useful oxidizing agent used in water treatment. CLO2 Services, LLC has incorporated a process that eliminates the hassle of generating Chlorine Dioxide. Utilizing a patented ClO2IX process, there is no chemical mixing and no electrochemical aspects required.

ClO2 is a highly effective eco-friendly microbiocide

It carries US Environmental Protection Agency (EPA), US Food and Drug Administration (FDA), and United Kingdom (UK) Government approval for many of its uses. ClO2 has been recognized since the beginning of the century for its disinfecting properties; and has been approved by the US EPA for many applications including widespread use in the treatment of drinking water. It is a selective oxidant that eliminates both planktonic and sessile bacteria, disinfects surfaces, and rapidly destroys biofilms.

Good for the Planet

Of the oxidizing biocides, chlorine dioxide is the most selective oxidant. Both ozone and chlorine are much more reactive than chlorine dioxide, and they will be consumed by most organic compounds.

No Harsh Chemicals

Chlorine dioxide however, reacts only with reduced sulphur compounds, secondary and tertiary amines, and some other highly reduced and reactive organics. This allows much lower dosages of chlorine dioxide to achieve a more stable residual than either chlorine or ozone.

Organic Technology

Chlorine dioxide, generated properly (all chlorine dioxide is not created equal), can be effectively used in much higher organic loading than either ozone or chlorine because of its selectivity.

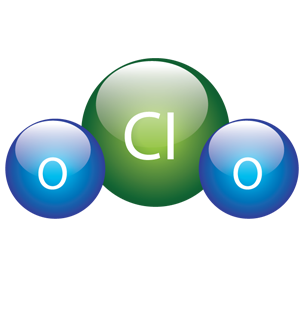

What makes up ClO2

- Yellow/Green in color

- Odor similar to chlorine

- Is highly soluble and stable in water at normal temperatures and pressures

- Remains 100% active in pH ranges from 5.0 – 9.0

- Chemical Formula: ClO2

- Molecular Weight: 67.45 g/mole

- Density: 2.4 times that of air

- Atomic Structure: 2-Oxygen atoms, 1-Chlorine atom

The commercial uses of ClO2 are many.

ClO2 is frequently used in refineries, power plants, and chemical processing plants to remove biofilm in a cooling tower, sterilize drinking water, protect Reverse Osmosis Units from biofilm, and sterilize oilfield type water.

One of the most common uses for Chlorine Dioxide is to sterilize cooling water basins and evaporation ponds. Cooling tower disinfection is important for two main reasons – microbiological control (including Legionella) and energy savings. Since there is a direct correlation between biofouling or a biofilm layer and the efficiency and heat transfer in a cooling tower, controlling this biofilm will improve heat transfer and lower the energy costs.

One of the most important industries in which ClO2 is used is the drinking water industry. ClO2 is routinely generated at municipal drinking water facilities to sterilize the water we consume every day. It is also used in bottled water plants to sterilize the containers, where drinking water is immediately added without rinse.

Utilizing the ClO2IX Process, we can now attack biofilm in Reverse Osmosis (RO) Systems. Biofilm is the last great challenge in reverse osmosis system design and operation. Biofilm can decrease the flux rate in a RO System, increase fouling, increase cleaning frequency, and cannot fully be removed … until now. Most RO membranes are made of thin film composite (TFC) material which is destroyed by traditional biocides such as chlorine or bromine. However, Chlorine Dioxide (when properly generated) does not damage the RO Membrane, and cleans both the reject and permeate side of the membrane.

ClO2 is valuable in the oil and gas industry because of its ability to sterilize oilfield type waters at near, non-detectable levels. This is especially important as government agencies get more involved. ClO2 can be safely generated on any oilfield site to eliminate bacteria in completion fluids, destroy biofilms, remove algae and slime, and deodorize impoundments by scavenging the Hydrogen Sulfide (H2S).

ABOUT US

About Us

CLO2 Services, LLC is an Industrial Service Provider of Chlorine Dioxide utilizing a patented generation process that minimizes risk to equipment while maximizing the inherent benefits that ClO2 brings as a biocide and sanitizer. CLO2 Services, LLC offers a wide range of generators for every application. Our process is not a batch process, so no storage is required, and we produce an inherently safe ClO2 solution with NO CHLORINE or OZONE in the product.

ENVIRONMENTAL

Environmental Impact

ClO2 is a strong biocide at concentrations as low as 0.1 ppm. With minimal contact time, it is highly effective against many organisms including:

- Bacterial Spores

- Biofilm

- Planktonic and Sessile organisms

- Algae

- Trihalomethanes (THM)/Haloacetic Acids (HMM)

- Legionella

- Tuberculosis

- Salmonella

- Cryptosporidium

- Giardia Cysts

- Coliforms

- MRSA

- VRE

- Listeria

- Shigella

- Amoebae

- Taste and Odor

CONTACT

Get in touch with us!

Corporate Office: 5224 Bear Creek Court, Irving, Texas 75061Contact: Office: 214.393.5009 Fax: 469.310.0382